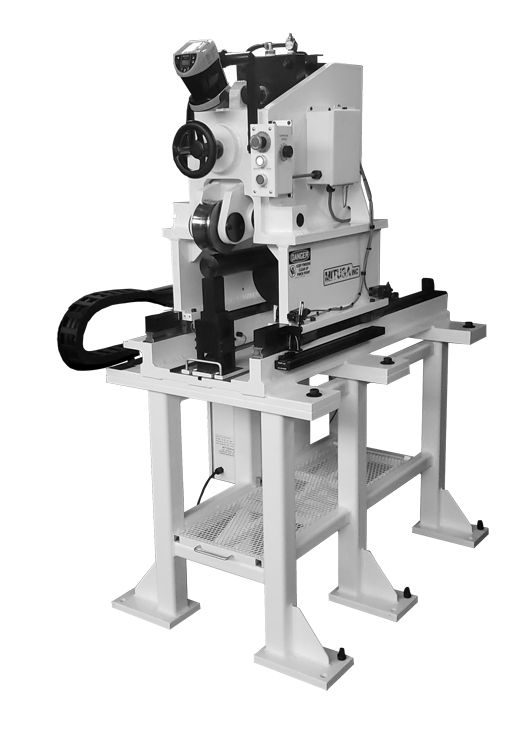

Longitudinal Planisher. Planishing machines are used for safely blending smooth the weld beads without the need for costly grinders, time consuming labor, discs and polishing wheel costs. Planishing eliminates the need for the expensive grinding and polishing of the weld beads by automating the lowering the weld crown profile. This is simply done by using the safe roll planishing process machine designs.

Custom Longitudinal Planisher Machines

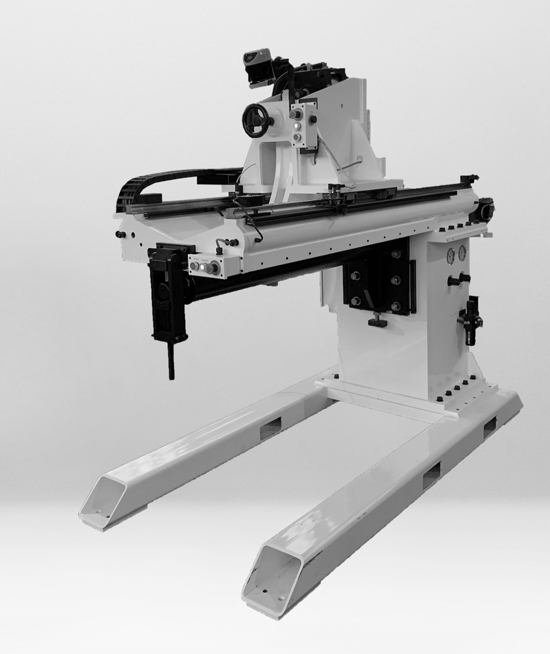

Finally there is a safe planisher tool called gantry longitudinal planishers that is a fastest way to flatten welds smooth while operating hands free during the planishing process. Planishing machines quickly and safely lower the weld bead profile using extreme controlled high pressure between the custom roller and harden steel tooling mandrel support. The planishers tooling configuration will maintain the part's original geometry after planishing the weld crown smooth is completely finished.

DC Welding provides the highest quality automated roller type linear planisher machines to customers domestic and internationally. The weld planishing process allows the operator to load the part into planisher support tooling and safely hands free planishing the seam weld flat into the part for a seamless smooth appearance. Standard and custom programmable automatic longitudinal planishers designed to replaced old unsafe manual planisher machinery.

Roll longitudinal planishers are used to flatten the weld bead smoothly on the OD and ID of the seam welded part. Weld planisher machines offer a fast safe affordable method to flattened the weld crown into a seamless appearance.

The automated planishing machine innovative technology by DC Welding is the definition of roll weld planisher automation designs. Manual or automatic gantry roll weld planishers for the safest operator welding planishers requirements.

The part hard working roll weld planishing process machines are manufactured for hands free operator safety. Easy precision weld part's planishing is now fully automated. Simple to complex custom roll planisher types, to our fully programmable automatic weld roll planisher designed systems available to meet specific requirement for your parts.

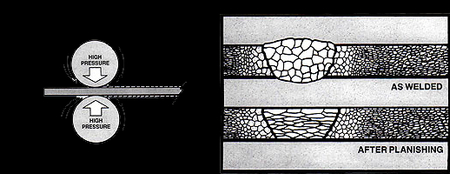

Longitudinal roller planishing process machines use high pressured hardened steel or stainless steel rollers and mandrel tooling that is built specific to your part's precise requirement. The harden planisher roll's pressure flattens smoothly blending the weld appearance without changing the shape of the original part. Planisher rollers using up to 20,000 lbs pressure to simultaneously eliminate the weld bead appearance and using cold hardening to improving weld strength once planish process is completed.

Industries that benefit by using weld planishers strengthening and flattening are metalworking fabricators, such as metal spinners, aerospace, aeronautics; petrol chemical, food processing. Everything from home appliances application to jet engines, rockets or anywhere critical precision weld removal and increased weld strength is required.

Roll type linear welding planisher designs that can safely flatten the seam weld smooth improving the product cosmetic quality and weld strength. Providing welding consulting and on how roll planishers may improve your ROI and productivity with automatic planisher systems. Used for blending thin tube bellows applications to sheet plate metal seam planishing and alloys applications and requirements. Roll planishers now safely allows the operator hands free planishing of welds on all type of parts and metal thicknesses.

Tube and Bellows Planishing Machine

Longitudinal planishing roller design process combines smashing or flattening that smooths out the weld crown and root weld bead. This produces a cosmetically uniform weld with a cross section thickness equal to that of the adjacent parent base metal or alloy.

Smoothing out the weld bead crown for flattened ID and OD finish on parts of all shapes and sizes. GTAW (TIG), GMAW (Mig/Mag) SAW (Sub Arc) PAW (Plasma) with any reasonable low crown weld bead seam weld can be flattened. Stainless, Carbon Steel, Aluminum, Inconel tubes are no problem. Planishing improves fluid flow characteristics as well as improving the appearance and strength of the tube.

Weld strength uniformity is important when weldments undergoes further metalworking processing such as bending, stretch and spinning. The longitudinal roll planishing actually improves the mechanical properties of the welded part making it stronger. This is dine by cold working pressure of the weld's columnar integrity and relieving normal stresses caused by the seam welding process.

Planishing welds adds strength and blends the weld bead ID/OD cosmetically smooth into the base metal while maintaining the part's shape.

The planishing machine metal finishing process including flattening the weld bead with automation can reduce costly grinding time and labor. The longitudinal roll planisher style is one of the least appreciated weld bead removal process methods available today. Unlike the costly sanding, grinding, which are all time consuming and labor intensive processes to fatten a weld. Roll weld planishers not only cosmetically remove a weld bead smoothly into the base material appearance quickly and safely.

The planishing of welds process is a roller and hard custom tooling with hydraulic pressure on the weld bead between the planisher roll and mandrel tool. The planisher roller must have the right precise geometry, allowing the roll pressure to smash the weld bead into the base metal as it cold-works strengthening the weld material. When our roll planisher tooling and part shape are just right with a smoothed seamless appearance. Planisher machines move in a linear fashion along the length of the part, pressing the weld bead flat while adding weld strength. Planisher rollers blend the weld bead and material on the OD/ID using tool steel hardened mandrel and custom roll tooling while equal opposite force is used to smooth the weld material on the ID.

Automated Part Clamping Bed Linear Planisher System